CNC – Computer Numerical Control

CNC stands for computer numerical control. It refers to a manufacturing method that automates the control, movement and precision of machine tools. It does so through the use of preprogrammed computer software, which is embedded inside the tools. CNC is commonly used in manufacturing for machining metal and plastic parts. However, United Stone Melbourne uses it for cutting our stone benchtops.

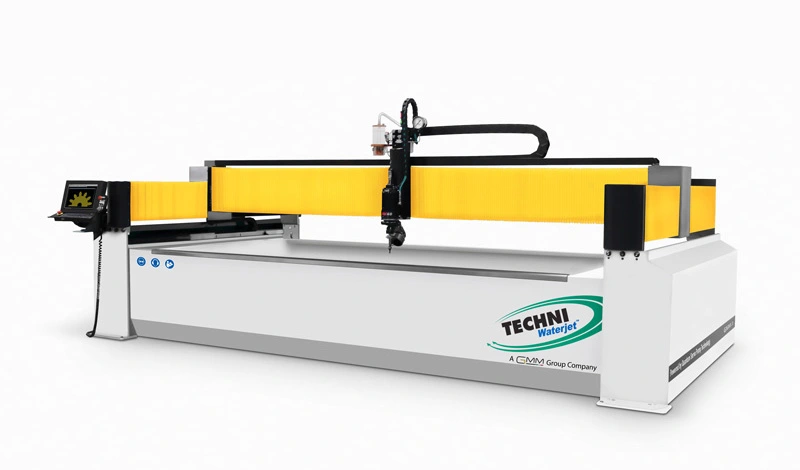

A waterjet CNC machine uses a pump to maintain a 55,000 to 100,000 psi pressure. How it works is, there is always a separate pump to build up pressure. The system has a quantum servo pump, which only requires one amp to maintain a pressure of 100,000 psi, while cutting. Maintaining that pressure while cutting, means it’s the most advanced quantum system or servo pump system in the market.

Waterjet CNC cutting is advanced, modern and unique ways of manufacturing porcelain benchtops. This is also a great technique for manufacturing any type of benchtop, including marble or granite. We use an Australian owned company in Campbellfield that poses a wealth of knowledge and the experience, they partner with a company called GMM, who are world leaders in Waterjet CNC cutting and stone manufacturing machinery.

The Waterjet CNC Cutting Process

- We have a porcelain Calcutta slab, called dhamma, in the machines, lying flat.

- The machine then calibrates itself, measuring the height and width of the slab before cutting.

- It has a 55-laser template on the computer. On the monitor you can see all the individual pieces required for that specific job. It even has the cut out for the tap and filtered water tap.

- On another monitor we have the picture of the kitchen, we have our lasers set up.

- In some cases, clients would like to keep existing features from the original kitchen. We base our templates for the cutting software off the existing layout and existing features that are to be kept. We want all aspects of the kitchen to flow together and work cohesively.

- We then have another monitor to overlook the modifications for the slab manufacturing and then we press the button to activate the laser.

Waterjet manufacturing, using laser templating gives us the ability to really do anything we want. You could have the most off square walls, the most unique tiles, or the most unorthodox design, but with our templating we can make it happen.

You can have peace of mind, knowing we can measure, manufacture, cut and install a benchtop of any shape and any material. Our machine produces nothing but accuracy.

We have been doing this for many years, we have seen it all. The best part about this manufacturing machinery, is that if we have the measurements, the slab can be cut with precision without a single blade.

To learn more and see a waterjet CNC cutting machine in action visit our ‘CNC Waterjet cutting & Porcelain Benchtops by United Stone Melbourne’ YouTube video.

We are very passionate about giving our clients the best of what’s available. We continue to make big investments in modern age laser templating, waterjet CNC manufacturing and being able to offer Porcelain as a recommended material for your Kitchen Benchtops.

In Our Video You’ll See The Benefits Of Porcelain

Porcelain is the most advanced surface, with its 100% scratch proof, stain proof, heat and UV proof capabilities it is the best choice. This is why you will see porcelain tiles on the floor and not engineered stone. Check out our video to witness how easily Kemal can wipe permanent marker off a porcelain tile, with a wet towel and some detergent. With one clean swipe Kemal removes the permanent marker with no residue or staining. Porcelain is made with a pigmenting process in a laminar machine, it gives the perfect pattern, making the colours extremely consistent, there’s never a variation in slabs.

To learn more about our porcelain benchtops call United Stone Melbourne on (03) 9791 3720.