People often ask about what materials a water jet cutting machine can cut. However, a better question would be what such a powerful tool cannot cut. This incredible technology can cut through anything with ease. However, special attention is required for certain materials with unique characteristics. If you’re looking for a list of materials that a water jet can cut, then continue reading on.

Stone

Water jet machines are a perfect cutting solution for a full spectrum of stone products, particularly kitchen stone benchtops. In a single operation, it can cut stone with precision, mitre edges, make tap holes, and cut sinks. Kitchen benchtops made from different types of stones, such as porcelain, granite, marble, etc., can all be cut using a water jet, making it the most valuable piece of equipment for the production of modern kitchen benchtops.

Composites

Cutting most composites is problematic for ordinary machines as they cause the machines’ tips to ‘gum up’, making them inefficient quite soon. A water jet machine, on the other hand, offers a great solution with no gumming whatsoever. Once the composite is cut, the machine leaves behind a clean surface that doesn’t require any additional work.

Alloys

Water jet machines also prove handy for cutting different types of alloys, such as Inconel, waspaloy, aluminium, Hastelloy, stainless, titanium, etc. With the use of water jet machines, the materials’ molecular structure remains unchanged, nor are they affected by heat. While using other cutting tools keeps the material under constant risk of distortion, water jet machines cause no such problems. Moreover, water jets are cheaper to use as compared to traditional cutting machines. The device doesn’t require any secondary removal of damaged material or slag, and you hardly see any burring.

Rubber

Rubbers with a high durometer value can either be cut with an abrasive or with water only. Tests reveal that water jet machines are the best machines for cutting anything made from this type of rubber.

Laminates

Water jet machines face no issues when it comes to cutting laminated materials such as acrylic, honeycomb, and aluminium. They are the only cutting solution for laminated materials that are installed in aircraft.

Fibreglass

Water jet machines also prove to be a safe solution for cutting materials characterised by hazardous fine airborne materials. To reduce the hazard and risk, water takes the removed particles and materials away from the surface and into the tank.

Acrylics & Plastics

Certain water jet systems not only cut acrylics/plastics with ease but also drill holes through their specialised, low-pressure features.

Glass

Water jet machines face no issues when it comes to cutting laminated materials such as acrylic, honeycomb, and aluminium. They are the only cutting solution for laminated materials that are installed in aircraft.

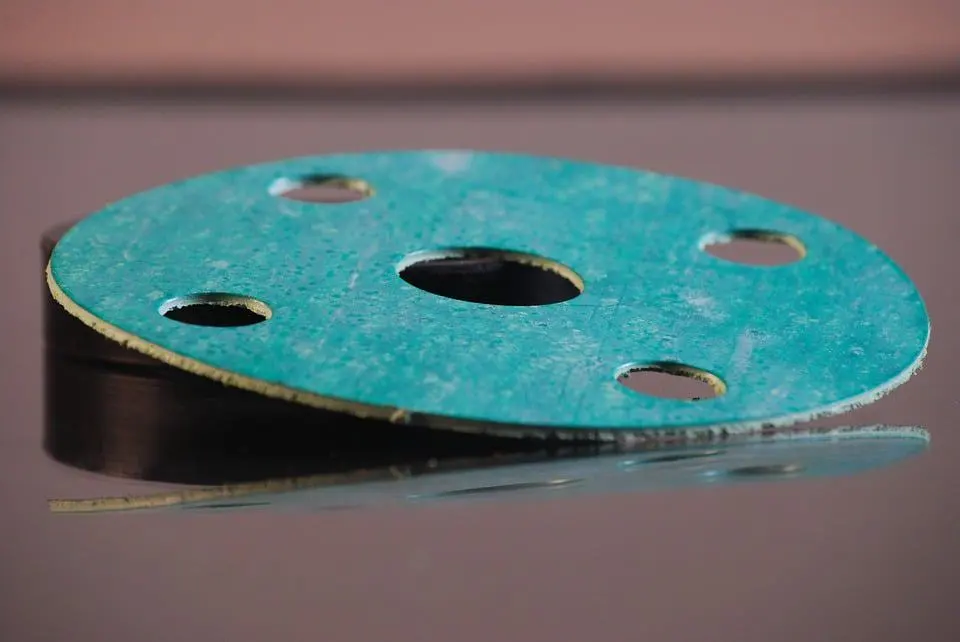

Gaskets

Water jet machines also prove to be a safe solution for cutting materials characterised by hazardous fine airborne materials. To reduce the hazard and risk, water takes the removed particles and materials away from the surface and into the tank.

To sum it up, water jet machines are multipurpose machines that can cut pretty much anything without facing any problem or posing any hazard. No matter which industry you belong to, water jet machines can help with all your cutting and shaping needs. If you’ve wanted to know what materials a water jet can cut, you now have your answer!