We Waterjet Cut Porcelain, Stone, Metals & more!

Water Jet Cutting In Melbourne

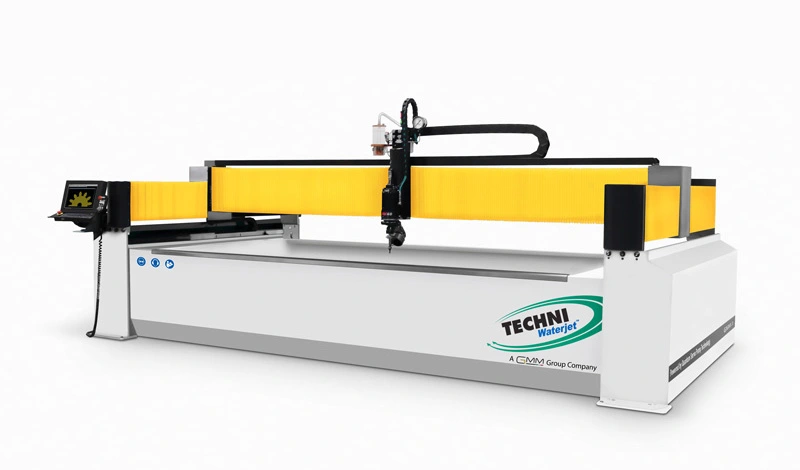

At United Stone Melbourne®, we use top of the range Techni GMM waterjet cutters which are made in Italy.

From intricate designs to custom shapes, we handle each project with care and precision, guaranteeing a perfect fit every time.

With years of experience supplying, cutting and installing various materials, we have specialist expertise in the stone masonry of all types of stone and sintered porcelain slabs.

Materials We Can Cut With The Techni GMM Waterjet

Equipped with advanced features and precise controls, our Techni GMM waterjet cutters are capable of cutting a diverse range of materials with unparalleled accuracy and efficiency.

With multiple axes and adjustable angles, including 5-axis and tilting head options, we can achieve intricate cuts and complex shapes with ease.

From delicate porcelain to robust metals, our waterjet cutter excels in handling varying thicknesses, speeds, and finishes, ensuring every piece is crafted to perfection.

Porcelain

Known for its durability and elegant appearance, porcelain is an ideal material for waterjet cutting. Its dense composition allows for clean cuts without chipping or cracking, while the waterjet's precision ensures intricate designs and seamless edges.

Marble

With its luxurious veining and timeless appeal, marble shines when cut with a waterjet. The waterjet's gentle cutting action minimizes the risk of damage to the marble's delicate surface, allowing for intricate designs and flawless finishes that enhance its natural elegance.

Granite

Renowned for its strength and natural beauty, granite is perfectly suited for waterjet cutting. The waterjet's ability to handle varying thicknesses and angles allows for the precise shaping of granite slabs, preserving their unique patterns and textures with exceptional accuracy.

Metals

Whether it's stainless steel or aluminium, metals shine when cut with a waterjet. The waterjet's high-pressure stream provides clean, burr-free cuts with minimal heat-affected zones, preserving the integrity and strength of metal materials while allowing for intricate designs and precise detailing.

Composite Materials

Combining strength and versatility, composite materials like acrylics and engineered wood are perfect candidates for waterjet cutting. The waterjet's ability to cut through varying thicknesses and compositions allows for custom shapes and designs, making it the ideal choice for creating bespoke solutions that exceed expectations.

Engineered Stone (Banned)

Engineered Stone has been banned in Australia and we can no longer supply or cut this material.Watch Kemal explain the ban on YouTube or for more information, visit the Australian Government website on the Prohibition on the use of engineered stone

What Is Water Jet Stone & Porcelain Cutting?

Through this highly refined process, our team creates exceptionally crafted products – including water jet cut splashbacks, benchtops, and many more concepts. A major advantage of this method is that it’s based around cold-cutting techniques. This means that, during the action of water jet cutting and laser drawing, the product is not put under unnecessary stress or pressure. This is especially useful when we need to cut extremely complex shapes that demand accuracy. Best of all, we can utilise a fine tip radius to create the highest water jet cutting detail possible.

Water Jet Cut Splashbacks

Using state-of-the-art laser templators, we produce highly defined .dxf cad files of your design. From here, we drop the file into our waterjet, where it’s then able to cut out exactly what the laser templator had measured up. As an example, you may have a crooked wall that requires an overlay. The laser templator will pick this up, and instead of cutting the back of your bench straight, our team will cut it to the shape of the crooked wall through lasering. This then sits up against the final result nice and flush.

This type of technology gives our team the ability to create highly refined, precise CAD drawings of your vision. Combining it with DXF drawings, the end-result is backed by a several-step, technical process.

Frequently Asked Questions

What is Waterjet Cutting?

Quantum Technology CNC Waterjet Cutting is using a Quantum Servo pump which only uses 1amp to maintain a cutting PSI of 55,000-100,000 and uses Water & Garnet (like sand) through a .5MM nozzle to slice though any type of surface. TheCNC component of the machine uses DXF (3D laser file) to cut to the shape and scribed walls of your upcoming benchtop. Our Waterjet is a TECHNI (Australian Made) and the operating software is GMM (worlds best). So there is NO blades, NO grinding, NO MDF templates, NO mistakes, NO dust. All waste is captured and is wasted in accordance to regulation and does not run into any stormwater.

Our dedication to this incredible, cutting-edge cutting technique shows our level of commitment to ensuring Melbourne homes are equipped with the most stunning finishes possible.

You will never see as incredible a finish on a benchtop as what you receive from waterjet cutting – the accuracy and sharpness of the finish is simply unparalleled. Our highly skilled and trained professionals have immeasurable experience in producing amazing results utilising this state of the art production technique.